PES has the versatility to manufacture one-off / batch / volume production of a large variety of components.

Our current manufacturing facilities includes:

| Turning (Gee Dee Wieler LZ 300G & Kirloskar 1330 Lathe) | |

|

|

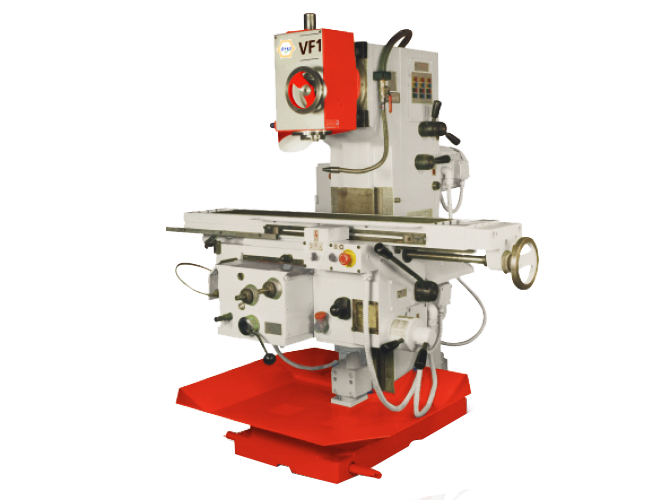

| Milling (HMT FN-1 – Universal with 3 axis DRO, BFW – Universal) | |

|

|

| Precision Drilling (HMT -M1TR with 2 axis DRO) |  |

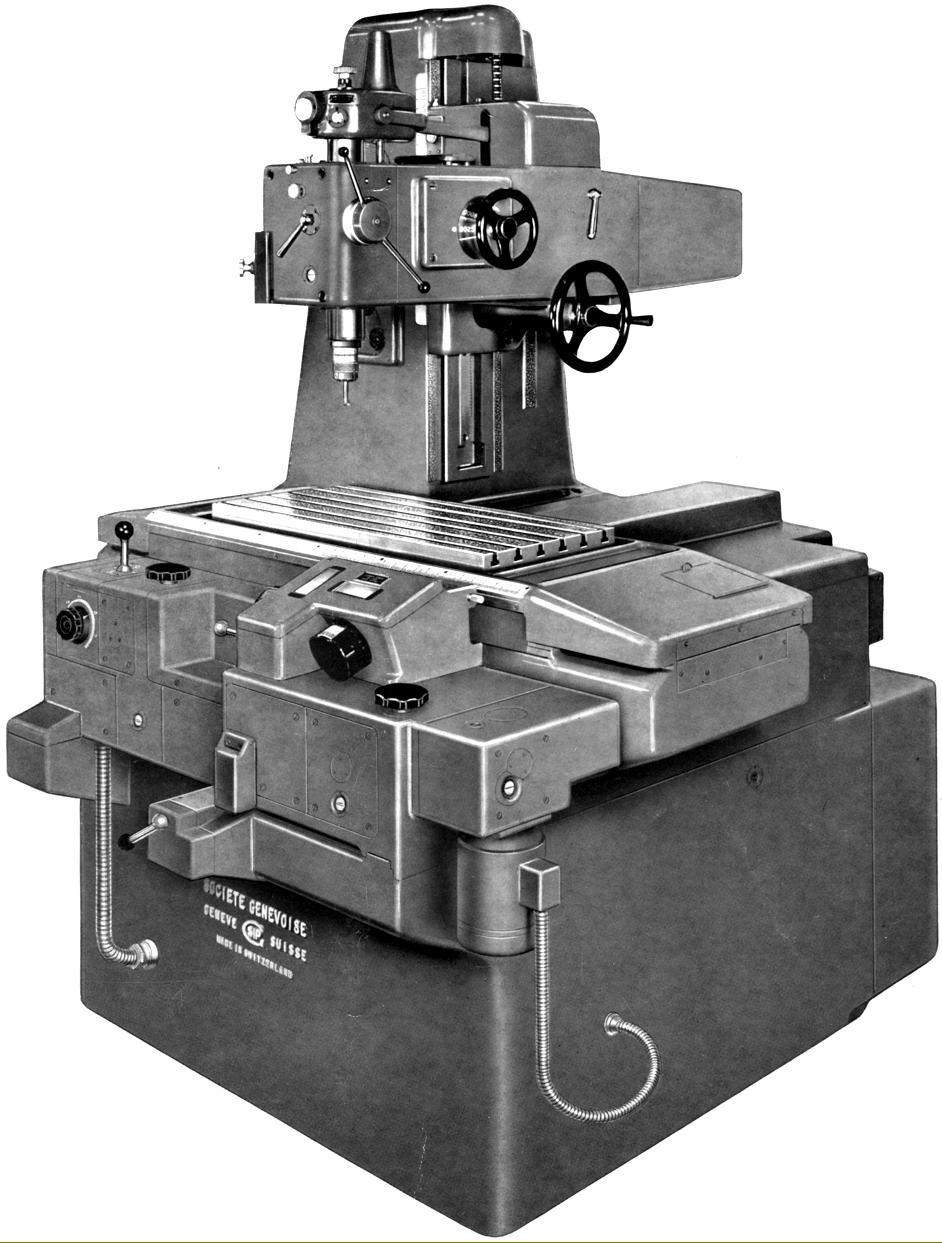

| Precision Jig Boring (S.I.P. with 2 axis DRO) |  |

| Panel Saw ( Jai Industries) |  |

| Precision Circular Sawing (Jai Industrie) |  |

| Vertical Band Saws (Jai Industries) |  |

| Surface Planner (Jai Industries) |  |

| Horizontal Band Saw (Sagar Industries) |  |

| Acrylic/Polycarbonate Bending. |  |

Specialised Toolings & Work Holding Devices:

| Dividing Head (Elliot) | |

| Rotary Table (Horizontal – Cum – Vertical) |  |

| Special Milling Machine Fixtures for manufacturing long & slender jobs like guides etc. | |

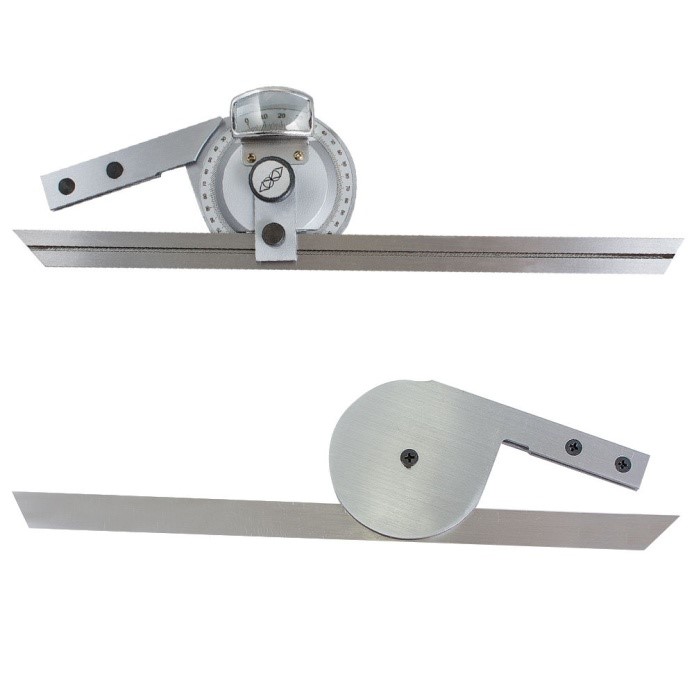

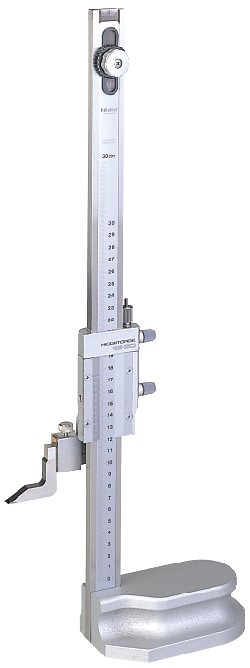

Measuring Equipments:

|

|

The addition of DRO’s to vital machines has multiple advantages:

- It facilitates precision error – free job setting / production.

- Reduction in setting time along with enhanced operator confidence.

- It helps in De-skilling / reducing skill dependency thus ensuring work completion by even semi-skilled operators.

Thus we get a precise & consistent output eliminating/minimizing costly rework at fractional cost of CNC machine.

No matter how complex the job, we have the technology, expertise and passion to deliver.